Orv, thank you for the poke, I meant to post an update to my repair but life got in the way. I am very happy with how easy the repair was to complete and how it turned out.

I had plates made by a local fab shop that were radiused to the contour of the van roof. They were not an exact match but close enough that I was able to pull them in place with the rivets. I painted the plates to match the van body before installing them.

I used a small die grinder and 3M abrasive pads to remove the paint down to bare metal. I drew an outline of the area the plates would cover and ground the paint off to within 1/4 inch of the edge of the plate. I wanted to be sure I didn't take paint past the plates to keep rust from forming.

I drilled small 1/8" holes at the ends of the cracks before installing plate to keep the cracks from continuing.

I used 3M 08115 auto body adhesive. This is used to adhere body panels and bumper panels and has a 3000 psi breaking strength. This is a 2 part epoxy and it requires a special applicator that mixes the parts as it is pressed out. I purchased both at a local auto body and paint supply store. The adhesive and applicator are also available on Amazon. There are aftermarket applicators which are cheaper than the 3M applicator but I wanted the project to go smoothly so I went with the 3M applicator.

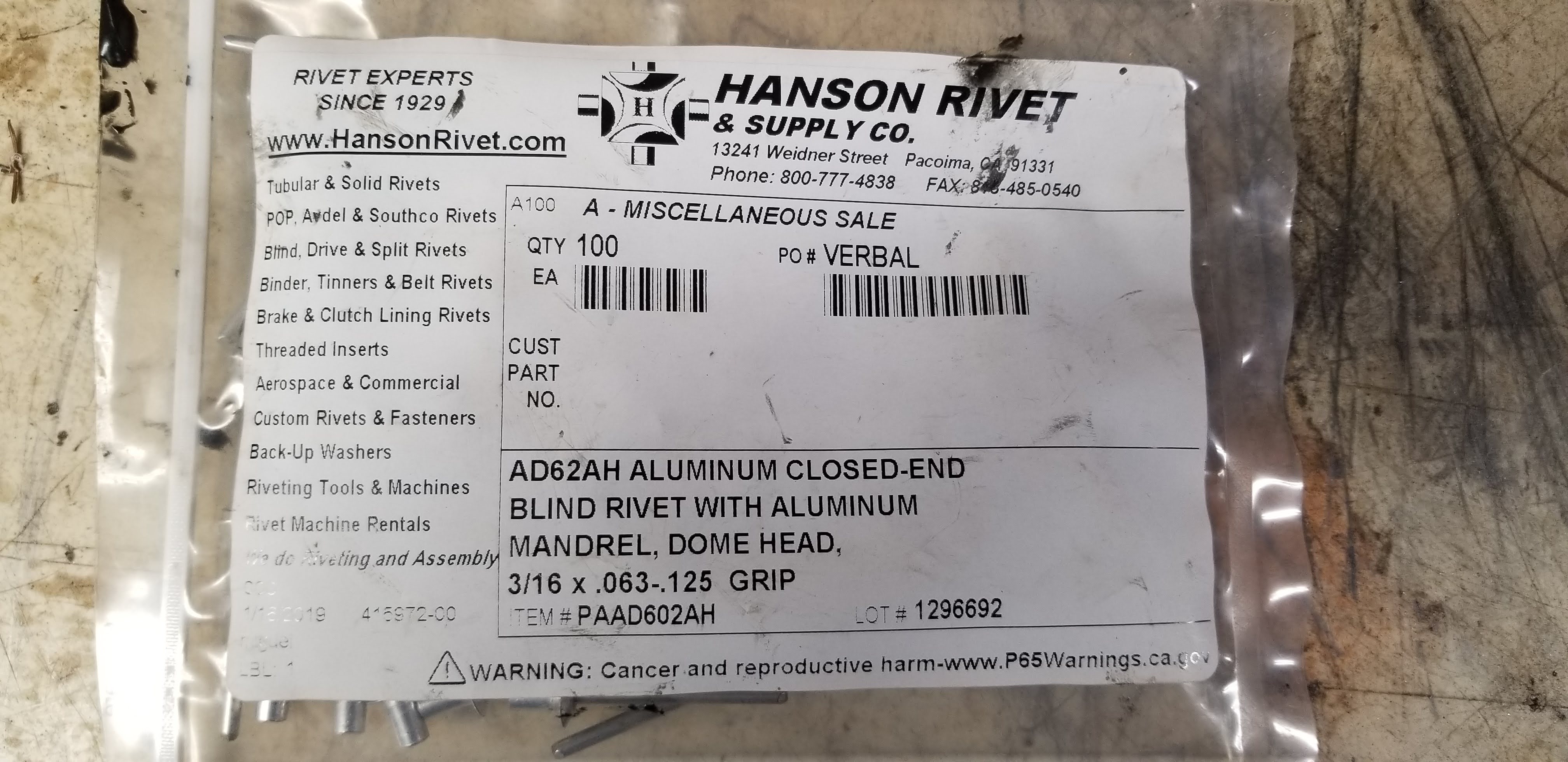

I ordered 3/16 closed end rivets with a grip of .63-.125. I brought them through Hansen Rivets,

www.hansonrivet.com. It is important to use closed end rivets to prevent water from leaking through the rivets. Most of the rivets you will find at local hardware store are open which could cause leaks.

I pre-drilled holes in the plates and two holes in the van body at the top corner of each plate to align the plates. I drilled the remaining holes as I installed rivets. This was because the plates didn't exactly match the curve of the van body and I wanted to avoid alignment problems.

I spread a generous amount of adhesive on the van body. I used a 1" plastic putty knife to evenly spread the adhesive over the area. This stuff is super sticky and you will need adhesive remover for the excess that comes out as you rivet the plate in place. There is a 3M adhesive remover specified on the package, which I didn't buy, but I found that Goo Gone did a great job of removing the excess.

Here are photos of the completed repair.

I am very happy with how the repair turned out and we have done some pretty tough 4x4 trails after the repair and there is no evidence of the cracks spreading.

I hope this helps anyone else trying to repair these cracks and am happy to answer any questions.

John