|

|

09-12-2017, 06:09 PM

09-12-2017, 06:09 PM

|

#11

|

|

Junior Member

Join Date: Jun 2017

Location: Chattanooga, TN

Posts: 26

|

Re: Sully - 1990 Ford E350 EB 121K Miles - Home build

|

|

|

09-13-2017, 02:07 AM

09-13-2017, 02:07 AM

|

#12

|

|

Junior Member

Join Date: Jun 2017

Location: Chattanooga, TN

Posts: 26

|

Re: Sully - 1990 Ford E350 EB 121K Miles - Home build

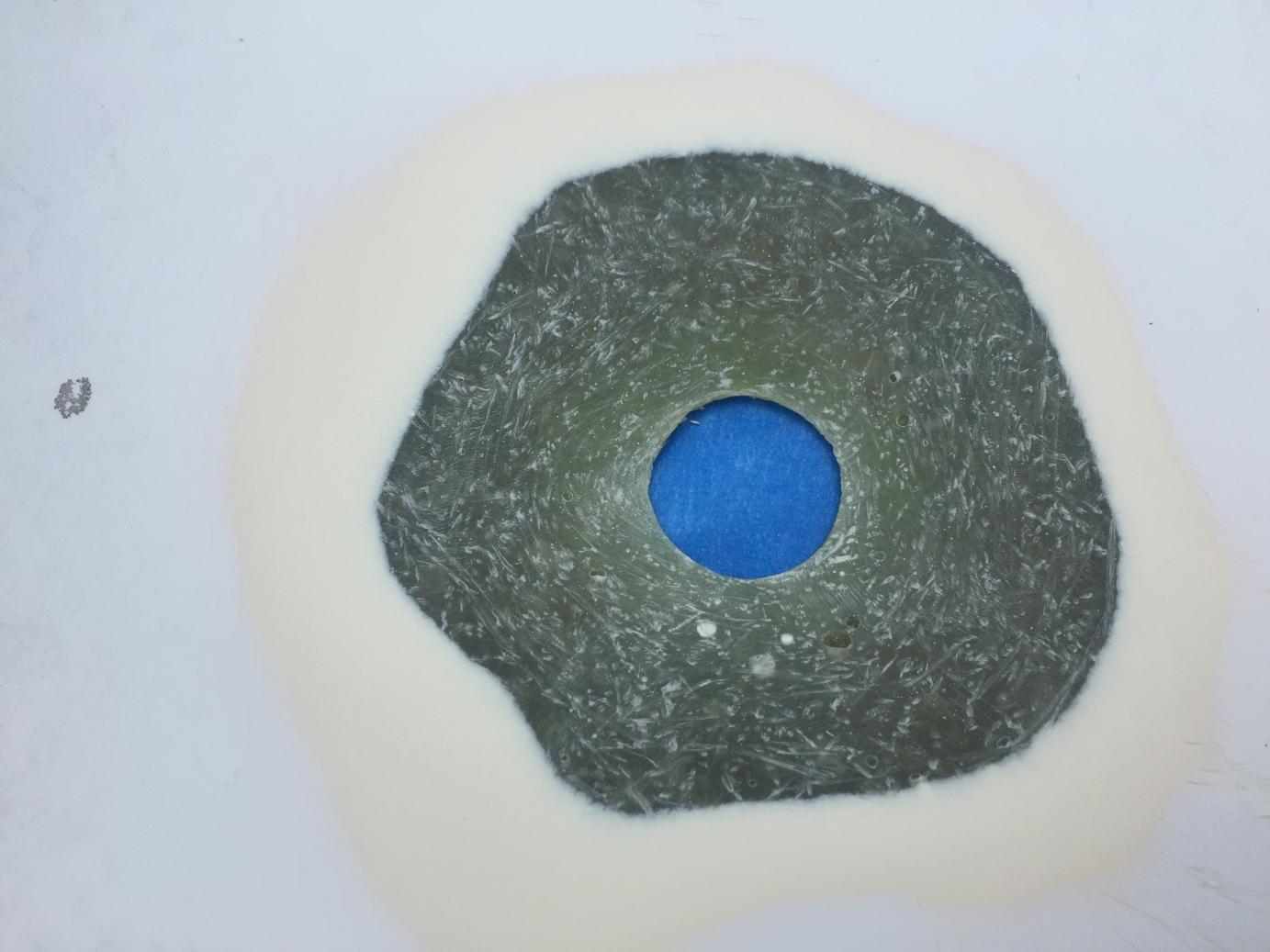

FIBERGLASS PATCHING:

Day 36 - Van Build: Patched a hole in the fiberglass high top roof left from an old TV antenna cable. Sanded the hole to make a tapered indent to glass in 4 fiberglass patches of increasing size. First time working with this bondo epoxy resin and you have to do it it quick. It was a hot sunny day and it hardened within 7 minutes. I'll sand and use body filler on the top coat later. Learning new things!

Setup the shop vac hose near the hole as I sanded the fiberglass. Wore respirator, eye protection, long sleeves, etc.

This cordless sander (multi tool) worked well. The triangle helps taper a small diameter a couple inches around the hole.

Masking tape on the underside so the patches and resin don't sag or drip. Comes off easy later.

Patched in 4 pieces of fiberglass matte with the resin of increasing size. Used a cheap paintbrush to dampened the resin (mixed with the hardener). Then used plastic squeegee to spread it out.

I'll sand this later and top coat it with Bondo body filler. Then paint. For now, just getting things water tight before I take a break from the van project.

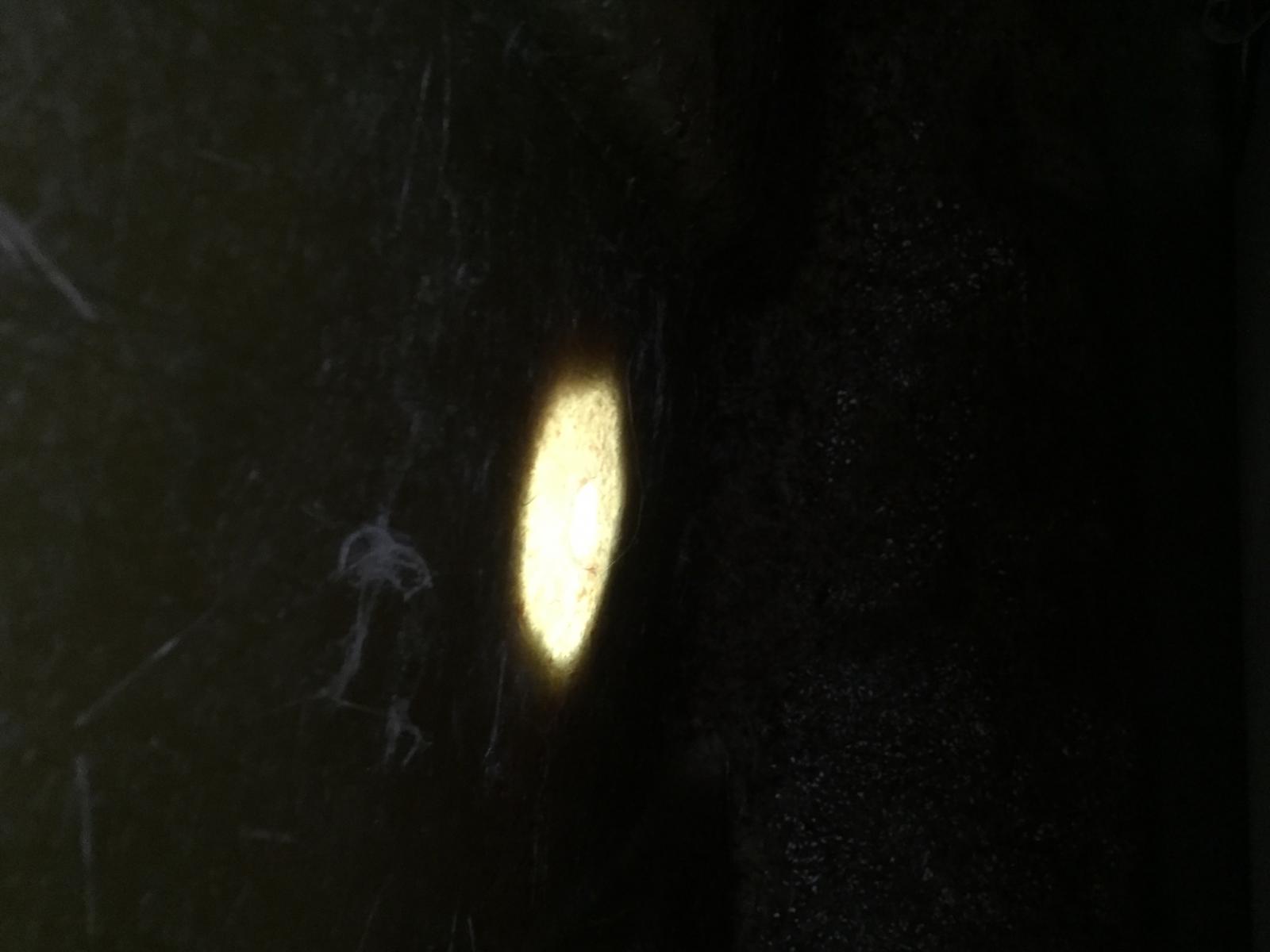

Patched 2 pieces of fiberglass matte on the underside of the hole. The light is showing through the resin now because there's no body filler or paint on the top.

Also, I found my roof leak culprit. I thought it was the weatherstripping and poor seal on the backdoors. But, there was a crack in the fiberglass high top right on top of the rear brake light where water could pool in.

Patched fiberglass hole with bit of fiberglass and resin. Then did an additional seal with black rv silicone. It got messy because my caulking tube and gun was acting up.

|

|

|

09-15-2017, 12:24 PM

09-15-2017, 12:24 PM

|

#13

|

|

Junior Member

Join Date: Jun 2017

Location: Chattanooga, TN

Posts: 26

|

Re: Sully - 1990 Ford E350 EB 121K Miles - Home build

JUNK YARD ADVENTURE:

Visited a couple junk yards with no luck. Then I found one yard with a couple pre-1991 Ford Econoline vans. I felt like I was in a jungle. It was a fun treasure hunting experience. And, I found a dead animal in one of the vans... eeeh.

Took a steering wheel cover since mine didn't have one. Also, I'm hoping I can reroute the horn to the wheel cover. Right now, the van came with a red horn button wired and taped to my drive gear shifter- a pretty janky job.

Found some grey trim I'm gonna switch out with my tan/brown trim.

Also took a rear tail light assembly because my old was cracked and the bulb assembly was duck taped in there.

|

|

|

09-16-2017, 10:19 AM

09-16-2017, 10:19 AM

|

#14

|

|

Senior Member

Join Date: Mar 2013

Posts: 4,244

|

Very nice, and that floor! Seems a shame to cover it up.

__________________

Arctic Traveller

KC6TNI

2001 GTRV

Advanced 4wd

Agile Ride improvement package

|

|

|

09-17-2017, 08:41 AM

09-17-2017, 08:41 AM

|

#15

|

|

Senior Member

Join Date: Jul 2011

Location: TN

Posts: 10,242

|

Looks like you found a good salvage yard, dead animals and all. Vans, being big dry boxes, unfortunately are a natural pick for critters in yards. It's a great house, why not move in! Also, salvage yard employees love to fill up vans with other parts since they'll be out of the weather. I've seen many decent van interiors destroyed from this, but it's not important to the salvage yard people. They don't see it like we do.

|

|

|

09-17-2017, 01:15 PM

09-17-2017, 01:15 PM

|

#16

|

|

Junior Member

Join Date: Jun 2017

Location: Chattanooga, TN

Posts: 26

|

FYI:

Floor Material Used

Noico 80mil Sound Deadener

x1 Sheet of 4"x8" Birch Plywood Purebond Soy 1/4" thick (Cut into strips for floor grooves)

(Note: The Purebond Soy product bought at Home Depot is suppose to be a healthier construction material compared to other plywoods which may off gas toxic formaldehyde from their glues.)

x3 Sheets of 4'x8' Rigid Polyisocyanurate Foam Board 1" thick

Floor foam seems taped with foil tape.

x3 Sheets of 4'x8' 1/2" Birch Plywood Purebond Soy

Foam board and 1/4" birch strips adhered with Great Stuff Pro and Gun Applicator. 1/2" birch subfloor is floating, no adhesion to 1" foam board.

|

|

|

09-26-2017, 03:50 PM

09-26-2017, 03:50 PM

|

#17

|

|

Senior Member

Join Date: Sep 2015

Location: Sandy, Utah

Posts: 418

|

Love the progress so far, can't wait to see the end result.

|

|

|

09-26-2017, 05:08 PM

09-26-2017, 05:08 PM

|

#18

|

|

Senior Member

Join Date: Nov 2012

Location: Brentwood, CA

Posts: 1,051

|

Cool build, I like the earlier body style. Great inexpensive platform to start from!

A word about the 460 cu in Ford big block: Not a lot of power, and not very good fuel economy. The exhaust runs hot and can be hard on catalytic converters if hauling a big load. Their are a few things that Ford did to achieve emissions targets in the 1980's on this older platform. Air injection into the exhaust manifolds, that acts as an afterburner of sorts, to clean up tailpipe emissions (Ford had to use more expensive cast steel manifolds, and $9 apiece titanium bolts to handle the high heat from this air injection. Ask me how I know  ). Fuel injection from 1988 up was a big improvement. But Ford also retarded the cam timing a power robbing 8 degrees(again to better meet emissions goals) that seriously reduced power of the big block to an anemic 240hp on a good day (mine felt more like 190hp). At rebuild time, using a different cam gear, cam chain and gear set from a pre '72, or different cam altogether will restore the cam timing, and regain the power this engine had in the early 1970's.

Other than than, that big block is bullet-proof, Ford mad eit forever so parts are very available, it should go 250k miles if it was driven by an adult and taken care of

__________________

1995 E350 7.3 Diesel, 4x4 high roof camper, UJOR 4" lift

|

|

|

03-27-2024, 03:36 PM

03-27-2024, 03:36 PM

|

#19

|

|

Junior Member

Join Date: Jun 2017

Location: Chattanooga, TN

Posts: 26

|

Selling Incomplete Project. 1990 Ford E350. Solar and Higher End Gear

Looking to sell.

I'll be updating and editing this post with more details on recent work...

Most of the cost/value is in the build equipment (solar/appliances/etc).

Looking to sell van and everything together... may be open to selling equipment as a package and van separately...

---

1990 Ford E-350 Extended Base Van with High Top

Camper Van RV Solar and High End appliances and equipment - Incomplete / As is

Odometer: 129,191 miles

Clean Title

Asking: $19,950 or Best Offer

Included Equipment: Solar (300 watts of roof panels, solar charger, 250aH battery power), Electrical (inverter/charger, distribution box, relay), Appliances (Fridge/Stove/Furnace/ASME propane tank), Water/Plumbing (fresh water tank, pump, sink, fixtures), and More (see below)

Looking for a buyer that wants to finish this camper van project of mine: Maybe you’re an experienced builder that can flip it. Or, a DIY person that can enjoy the insulated van and bed platform for trips and take on the needed projects later.

I was hoping to finish the rest of the work (paint/electrical/plumping/propane) and then sell it, but I may sell it as is. I purchased the van in Michigan in 2017. Previous owner used it as a work van and said it spent much of its previous life as a church van in Florida. I worked on it during summers and the pandemic.

I was designing it for full-time off-grid van dwelling for a single person or a weekend warrior for 2 people, capable of 4-seasons (insulation and furnace). I didn’t cheap out on any appliances, fixtures, or hardware (ex: Propex furnace, stovetop, ARB fridge, Elkay sink, Doulton 2-stage water filter, Lagun swivel desk/table).

Van is currently tarped and stored in Michigan. I am currently in Tennessee.

I’ve taken a couple cross country road trips with it. It runs well and has been reliable.

The majority of the woodwork is done, the most recent cabinets and ceiling panels still need primer/paint (included) and need to be secured. Boxes are built for kitchen drawers but the sliders and faces need to be assembled. A few sidewall panels and the front cab/headliner needs to be finished. Then, it’s mostly propane tank/stove/furnace install, electrical/solar install (300 watts of panels already installed on roof with wire entry), and plumbing install. The majority of the equipment is included. The few additional expenses needed would be electrical wire and plumbing pipe.

I’ll try to be as detailed as possible with all included equipment, work done, and will answer questions for serious parties and offers. The transaction may have to be done via my dad in Michigan, or I may have to travel from out-of-state. Ideally, I answer as many questions as possible in writing, with photos, or by phone, you check out the van in person, and if you want to buy it, we load all of the equipment and materials included which is currently stored indoors elsewhere.

(The green rugs are just to protect the vinyl plank flooring while working.)

Van:

1990 Ford Econ0line EB Van

Engine: 7.5L V8 460 cu

Tires: Cooper Discover M+S Snow tires, LT265/75R16, 16” Rims

Spare Rim/Tire: Included

Spare Tire Carrier: Surco TF100 Rear Door Tire Carrier (This model is suppose to fit this van, I think iit may require some modification or finagling to fit.)

Rear Backup Camera and LCD Monitor: Esky Rear backup camera (installed with wire entry. Still needs to be wired to included LCD monitor.)

Electrical:

Solar Panels: 300 watts total = x3 100 watt Renogy Monocrystalline solar panels already installed on roof with wire entrance.

Solar Charger: Midnite Solar Kid (white) (Whizbang Jr, shunt, and accessories included)

Inverter/Charger: Tripp Lite Pure Sine 1000 Watt Inverter/Charger APS1012SW

Isolator: Blue Sea Systems 7622 Smart Isolator (charges batteries when driving)

Batteries: 250aH total = x2 VMAX 12V 125aH Battery

AC/DC Distribution Panel: WFCO WF-8930/50 (6 AC / 15 DC fuses) All in one AC/DC compact power control panel

Ceiling Lights x11 (brass) – LEDs - 3.2 Watt energy usage, 12 Volt, .24 Amp draw, 120 Lumens

Appliances:

Refrigerator: Arb 50QT Fridge - 0.7-2.3aH usage

Ceiling Fan: Maxx Fan Deluxe (White color. Installed on roof, still needs to be wired) – DC 4.0A high – 0.2A low

Propane:

Furnace: Propex HS2000 with additional noise Stealth Kit accessory - 1.4A (continuously running)

Stovetop: Dometic/Smev PI8022 2 Burner Cooktop Stove Range (Pizeo ignition, no 12v connection needed)

Propane Tank: 7.9 gal (33 lbs) ASME Manchester 6814 Tank 10” diameter x 32” length (To be mounted underneath van.)

Propane Detector – 12v DC - .09A

Carbon Monoxide Detector – Battery Powered

Dual Smoke Detector – Battery Powered

Water/Plumbing:

Fresh Water Tank: 20 gal Water tank 14” x 28” x 11.5" (fits inside rear bed cabinet to stay insulated for winter), standard fittings

Water Pump:

Shurflo Revolution Standard 12v Automatic Demand Pump Classic RV Pump 4008-101-E65

SHURFLO 94-591-01 Pump Silencing Kit

SHURFLO (255-313) 1/2" Twist-On Pipe Strainer

SHURflo 182-200 Pre-Pressurized Accumulator Tank,Black

Drinking Water Filter:

Doulton Hip Duo (W9380001) 2 stage undersink water filter

Doulton W9240002 Water Sediment Pre Filter

Doulton Ceramic Filter

Sink:

Elkay Crosstown Sink 3-hole 15”x15”x9" (sound dampening)

Elkay Strainer and Camco Drain

Kraus Oletto Kitchen Bar Faucet Stainless Steel

Kraus Purita Faucet Water Filter

Kraus Soap Dispenser

Grey Water Tank:

7 gal Reliance Aquatainer (sits below sink)

Cabinetry:

Desk/Table: Lagun Marine RV Swivel Table Base (Table/desk converts to hallway piece for full-size bed platform)

Bed platform and cabinetry made of ¾” birch plywood. Single bed can convert to full-size bed with hallway inserts to sleep 2 people.

White laminate countertops.

Hardware: Brass cabinet handles and custom door handles included.

Flooring:

Rear: Noico 80 mil sound deadener, 1” rigid insulation, ½” birch subfloor, LifeProof Vinyl Plank flooring

Front Cab: Noico 80 mil sound deadener, Mass loaded vinyl MLV sound deadener with ¼” foam backing

Insulation:

Floor: 1” Rigid polyisocyanurate foam board insulation

Side walls: 1” (2” near bottom third) Rigid polyisocyanurate foam board insulation

Ceiling: ½” Rigid polyisocyanurate foam board insulation

Doors: 4” Rockwool Mineral Wool Batting

Auto Work:

Purchased van 2017. Parked in driveway while worked on it-not much driving miles.

11/11/17: Replaced fuel gauges and power windows fixed

9/12/18: Replaced Distributor Cap, Distibutor Rotor, Spark plugs, Ignition wire set, PCV valve, PCV Grommet

6/16/18: Replaced thermostat and thermostat gasket

9/18/18: Replaced fuel filter, radiator cap

9/18/18: Oil change synthetic and filter

9/19/18: Replaced brake pads Semi-Met BB MKD120

9/19/18: Replaced turn signal switch and wiring

Cross country road trip Fall 2018.

Weekend trips and driving mileage throughout 2019.

1/4/19: Replaced battery

7/4/19: Replaced alternator Remy New 922103 80amp 2 plug w AC o clock plug, 6 groove

Cross country road trip fall 2019.

9/19/19: Oil change synthetic

Van parked for most of 2020-2021 while working on build out.

Van parked and stored since winter 2021. Starting it up and running the engine about once a month.

Some auto van work to be done:

-Passenger door has rust-through (I think from old bondo work) about 8”x18”. I was going to experiment with fiberglass matte and bondo work… but likely was going to pull a salvage door from a junk yard van.

-A small lower panel of glass from the 3 panel window behind the driver’s door is missing. Previous owner had a piece of plywood fitted and caulked that was painted black.

-There’s some bondo work to the lower left of the passenger

-I was planning to replace all the hoses but never got to it. I’d recommend that in the near future as a preventive measure.

-I was just in MI and it starts up and runs just fine. The brakes are spongy so the brake fluid should be bled and replaced before it travels far.

__________________

1990 Ford E-350 EB - Home Build in Progress - 121K

https://www.sportsmobileforum.com/forums/f24/sully-1991-ford-e350-eb-121k-miles-home-build-19738-2.html#post212897

|

|

|

03-27-2024, 03:36 PM

03-27-2024, 03:36 PM

|

#20

|

|

Junior Member

Join Date: Jun 2017

Location: Chattanooga, TN

Posts: 26

|

__________________

1990 Ford E-350 EB - Home Build in Progress - 121K

https://www.sportsmobileforum.com/forums/f24/sully-1991-ford-e350-eb-121k-miles-home-build-19738-2.html#post212897

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|