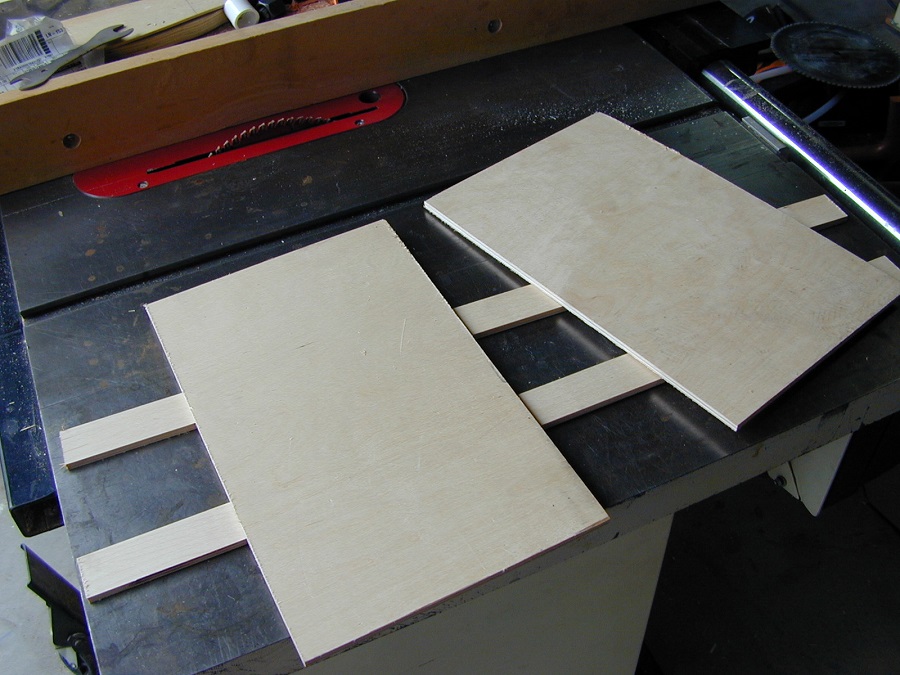

I played around with a couple of methods for building lightweight interior cabinet panels today.

It's a pretty simple idea.......the center layer is strips (I have plenty of leftovers!) with outer skins glued and stapled together.

The first experiment was using 3 layers of 1/4" Baltic birch to create a lightweight 3/4" panel.

I also glued up another piece the same size as the original using 1/2" center strips with 1/8" skins; this also yields a 3/4" thick panel for those who are math-challenged.

Here is a comparison with weights-all panels are the same size:

(top to bottom)

3/4" Baltic birch 1 lbs 12 oz

3/4" Chinese import birch 1 lbs 7 oz

I know this one has biscuit grooves in it....if this was for a peer-reviewed journal I would have found a non-grooved piece...

close enough for van work...

1/4-1/4-1/4 inch sandwich 1 lbs 7 oz

1/8-1/2-1/8 inch sandwich 1 lbs 4 oz

If you want to be a real "weight weenie", then you could always try 1/8-1/4-1/8 sandwich for 1/2" total panel thickness or 1/8-3/8-1/8 for 5/8" panels.

Keep in mind the weights above are somewhat "worst case" since actual van interior panels are typically much larger and will have more "air" inside if you use skinny strips for the "jelly" part of the sandwich.

Downsides to this method:

it takes time, glue and staples

you have to plan ahead a little if you need part of the panel to be solid (for example for bolting other things to the panel). Perhaps not much of an issue with the 1/4" sandwich but probably an issue for the 1/8-1/2-1/8 sandwich.

To get a clean end result, it helps to make the panel slightly oversize and make the final accurate cuts on the completed layer cake. Curved panels require a laminate trimmer bit for clean edges.

1/8" skins may not be robust enough for puncture resistance....the 1/4" skins certainly are...

Upsides to this method:

Whatever thickness material you use for the center goes a long way, and the outer skin material is relatively cheap...but you need two outer skins most of the time.

The panels are light.