|

|

12-19-2021, 04:46 PM

12-19-2021, 04:46 PM

|

#1

|

|

Senior Member

Join Date: Apr 2007

Location: SF Bay Area, CA

Posts: 1,289

|

Long shot request - Ring & Pinion set up tools

So, this isn't for my van but attempting to set up new ring & pinion in front axle of a very budget project (1975 K20 pickup that was gifted to me). I seem to be accumulating bad front axles for the front of this and am settling in on making one good one out of a 10 bolt GM-8.5".

Never set up gears but giving it a try especially since it is the front axle and not all the time drive axle. I understand the basics of it and am technically oriented, so why not ...

Any gear-heads out there have any of the following I could borrow?

- Pinion depth gauge

- Backlash gauge

- rotational torque gauge to set pre-load

I'm in the SF Bay Area (East Bay) and happy to come and get them.

Again, this is a long shot but figured I'd ask. Not tools I will likely ever use again so don't want to buy them.

Thanks!

__________________

Phil

- 2005 EB50 6.0PSD - SMB 4x4

|

|

|

12-21-2021, 07:57 AM

12-21-2021, 07:57 AM

|

#2

|

|

Senior Member

Join Date: Jan 2011

Location: Reynoldsburg, Ohio

Posts: 3,771

|

Someone here close should have most or all of what you need---hopefully anyway.

Maybe watch a few YouTube videos on R&P set-up, could be you have some or most of what you need already?!

|

|

|

12-22-2021, 10:09 AM

12-22-2021, 10:09 AM

|

#3

|

|

Senior Member

Join Date: Jul 2013

Location: So Cal

Posts: 4,067

|

You don't need a pinion depth gauge......start with the shim stack in the axle you are installing the new gears into, it should be close. Paint a gear pattern, that will tell you where you are. Start by moving in big increments....around .010"....then when you get close .002"-.003".

To measure backlash just use a cheap dial indicator on a magnetic base. The indicators can be found for around $20 and the bases also around $20.

To measure the pinion preload torque you need an inch-pound dial or beam type torque wrench, which will usually be 1/4" drive and two drive adapters to get you to 1/2" drive for the pinion nut (1/4" drive to 3/8" and 3/8" drive to 1/2"). A click type torque wrench could work but would be a headache.

__________________

2008 E350 RB passenger 4WD SMB penthouse

2013 KTM 350 EXC

2008 KTM 250 XCF-W

2003 Honda Element

|

|

|

12-22-2021, 10:32 AM

12-22-2021, 10:32 AM

|

#4

|

|

Senior Member

Join Date: Apr 2007

Location: SF Bay Area, CA

Posts: 1,289

|

Quote:

Originally Posted by boywonder

You don't need a pinion depth gauge......start with the shim stack in the axle you are installing the new gears into, it should be close. Paint a gear pattern, that will tell you where you are. Start by moving in big increments....around .010"....then when you get close .002"-.003".

To measure backlash just use a cheap dial indicator on a magnetic base. The indicators can be found for around $20 and the bases also around $20.

To measure the pinion preload torque you need an inch-pound dial or beam type torque wrench, which will usually be 1/4" drive and two drive adapters to get you to 1/2" drive for the pinion nut (1/4" drive to 3/8" and 3/8" drive to 1/2"). A click type torque wrench could work but would be a headache.

|

Thanks Boywonder. I know I don't need a pinion depth gauge, but figured if someone had one it could make life easier. A wonderful forum member has agreed to let me borrow his indicator for backlash and inch-pound dial wrench (and something to hold the pinion while torquing the nut). I'll hopefully pick them up next week and get to work on this.

I have a standard inch-pound torque wrench but I imagine to get rotational readings would be a bit of a guessing game with that.

I'm actually enjoying working on this junker of a truck as it is a great learning project on something that if I mess up it doesn't matter that much.

__________________

Phil

- 2005 EB50 6.0PSD - SMB 4x4

|

|

|

12-22-2021, 11:49 AM

12-22-2021, 11:49 AM

|

#5

|

|

Senior Member

Join Date: Sep 2013

Location: Newberg, OR

Posts: 1,385

|

Quote:

Originally Posted by pjpvi

...this junker of a truck...

...it doesn't matter that much...

|

How dare you blaspheme thine sacred Squarebody!!!

The way the posts are reading here, it sounds confusing. To clarify, the inlb torque wrench is to get a value for bearing preload (essentially measuring the amount of resistance or drag on the bearing). It is a very light resistance, on the order of 5-30inlb and really only measurable with the "beam" style torque wrench or dial style or digital... not click type. You are not tightening anything with this torque wrench, just using it to measure bearing preload.

The pinion nut torque is probably at least 80 ftlb and can be in the 200+ range on some rigs.

I thought this video was really good explaining the process of finding pinion depth, setting backlash and reading the pattern on the gears. Very detailed

https://youtu.be/8yp1ky-F6YE

|

|

|

12-22-2021, 01:07 PM

12-22-2021, 01:07 PM

|

#6

|

|

Senior Member

Join Date: Apr 2007

Location: SF Bay Area, CA

Posts: 1,289

|

Quote:

Originally Posted by mgmetalworks

How dare you blaspheme thine sacred Squarebody!!!

The way the posts are reading here, it sounds confusing. To clarify, the inlb torque wrench is to get a value for bearing preload (essentially measuring the amount of resistance or drag on the bearing). It is a very light resistance, on the order of 5-30inlb and really only measurable with the "beam" style torque wrench or dial style or digital... not click type. You are not tightening anything with this torque wrench, just using it to measure bearing preload.

The pinion nut torque is probably at least 80 ftlb and can be in the 200+ range on some rigs.

I thought this video was really good explaining the process of finding pinion depth, setting backlash and reading the pattern on the gears. Very detailed

https://youtu.be/8yp1ky-F6YE |

Haha - don't worry, I love the square body!

I simply don't have any real plans for this particular project other than getting it to mechanically drive well and finishing what the kid neighbor started (who as it turns out really didn't have a clue what he was doing). Then I may take it up into the mountains and wheel it or I may get some good body parts and make it look nice or ...??? It just fell in my lap one day and being retired and not traveling a lot at the moment, it's a good learning project that keeps me somewhat out of trouble.

I understand the torque of the nut vs rotational drag and have watched a number of videos. Another one will certainly not hurt so look forward to watching it.

Thanks!

__________________

Phil

- 2005 EB50 6.0PSD - SMB 4x4

|

|

|

12-22-2021, 01:12 PM

12-22-2021, 01:12 PM

|

#7

|

|

Senior Member

Join Date: Jul 2013

Location: So Cal

Posts: 4,067

|

Quote:

Originally Posted by mgmetalworks

The pinion nut torque is probably at least 80 ftlb and can be in the 200+ range on some rigs.

|

Yup...the pinion nut torque on a Dana 60 is 250 Ft lbs....PITA on your back on the ground with a giant torque wrench.

pjpvi: When you get going post some pics of your patterns......I'm sure there will be a few of us who can comment. It can be confusing at first to decipher....but after you've installed/removed/shimmed/adjusted a dozen times or more it starts making sense.

__________________

2008 E350 RB passenger 4WD SMB penthouse

2013 KTM 350 EXC

2008 KTM 250 XCF-W

2003 Honda Element

|

|

|

12-22-2021, 01:31 PM

12-22-2021, 01:31 PM

|

#8

|

|

Senior Member

Join Date: Apr 2007

Location: SF Bay Area, CA

Posts: 1,289

|

Quote:

Originally Posted by boywonder

pjpvi: When you get going post some pics of your patterns......I'm sure there will be a few of us who can comment.

|

OK, but be gentle on me. This is my first time.

__________________

Phil

- 2005 EB50 6.0PSD - SMB 4x4

|

|

|

12-22-2021, 07:48 PM

12-22-2021, 07:48 PM

|

#9

|

|

Senior Member

Join Date: Sep 2013

Location: Newberg, OR

Posts: 1,385

|

I thought this guy's video was good at explaining how the gear pattern moves with changes to pinion depth and backlash.

https://youtu.be/nVb5WRUfM7Y

This is another good visual representation of how things interact to create the pattern.

https://youtu.be/w2kneEjXw6E

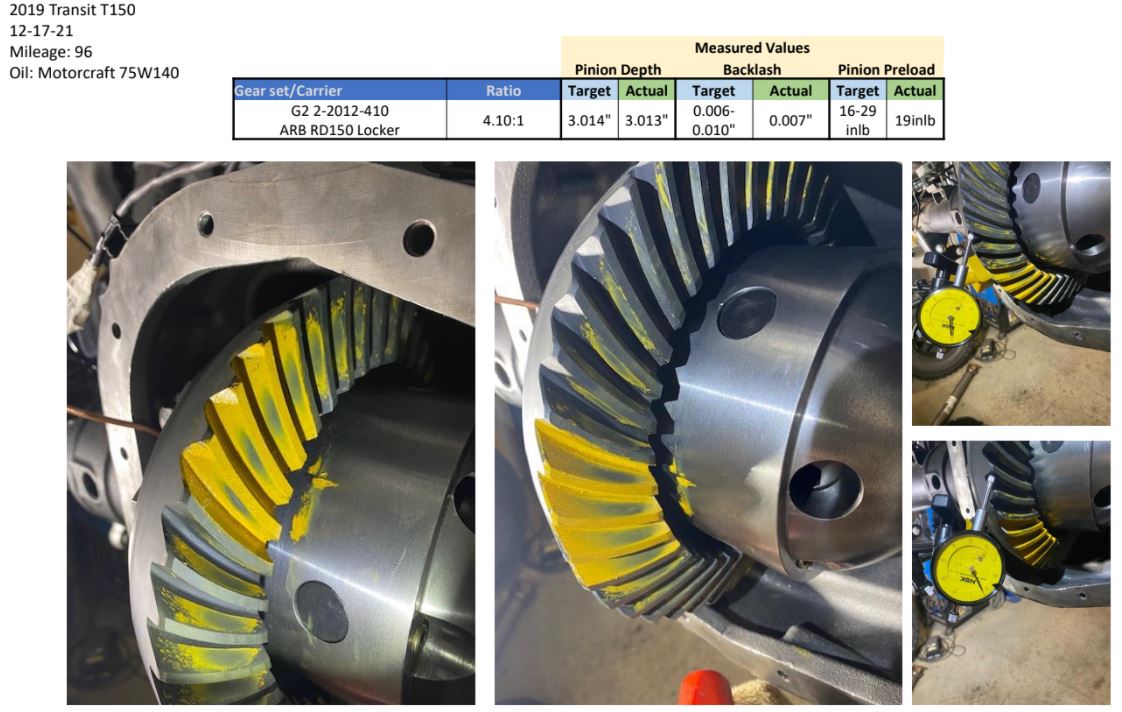

I just did a re-gear and ARB install in a Transit last week and since it had been a while since my last gear change rodeo, I watched several videos to refresh. Of all the videos I've seen, the two here and the one I posted previously seemed to have the best practical explanation.

I like to document this stuff so I can reference what I did if there are any issues. For all the combinations of shims that I tried (and there were many), this combo provided the best "squish" of the gear marking compound. No hard edges, just a nice diffuse pattern on the tooth. Do make sure that you put some resistance on the ring gear as you're spinning for a pattern.

Also remember than some gearsets just won't make a great pattern right in the center of the tooth. You can still get an acceptable pattern though...just don't bury yourself in the root or hang off the edges of the tooth.

|

|

|

12-22-2021, 08:47 PM

12-22-2021, 08:47 PM

|

#10

|

|

Senior Member

Join Date: Apr 2007

Location: SF Bay Area, CA

Posts: 1,289

|

Those are some nice patterns Mr. MG. I'll see how I do once I dig into it. Thanks for the video links.

__________________

Phil

- 2005 EB50 6.0PSD - SMB 4x4

|

|

|

|

|

| Thread Tools |

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|