I have recently installed my EB penthouse on my Van. The penthouse was a junkyard find and all the work was done by yours truly. It works, It fits, Its water tight. However, Its heavy. Very Heavy. I Can lift it and lower it unloaded, but my girlfriend cannot. I am a healthy 25 year old male and this thing is still hard for me. I can get the top up and down just fine unloaded, but when I added my empty thule cargo box with load bars (~40lbs) to the rear I about pulled a hernia getting it up. I havent even tried loading it or adding my solar panels. I know the panels up front will distribute the load better. they weigh about 10 more pounds than the empty box, but I would like to be able to add about 20#-30# worth of stuff in the box. EIther way I want my girlfriend (and the person who buys the van when Im done) to be able to easily lift and lower the penthouse.

I have made a number of modifications to the penthouse that I thought would make it smooth and easy.

- Sleeved the bars(per recommendation of Boywonder)

- Shoulder bolts

- removed 3 links from the chain

- greased everything up

The only thing I havent done is add a small block behind the assist spring. While I had everything apart I took some time to run some tests on the springs and make some free body diagrams. The large spring has a value of 14#/inch with an initial pull requiring 45#. The small assist spring has a value of 40#/inch. I dont know if this is true for any other EB penthouse than mine. My penthouse came from Austin in the mid 90s.

I know sportsmobile can modify the penthouses for you, but I dont have $3500 to blow. I dont think they would take me anyways because I did the install myself.

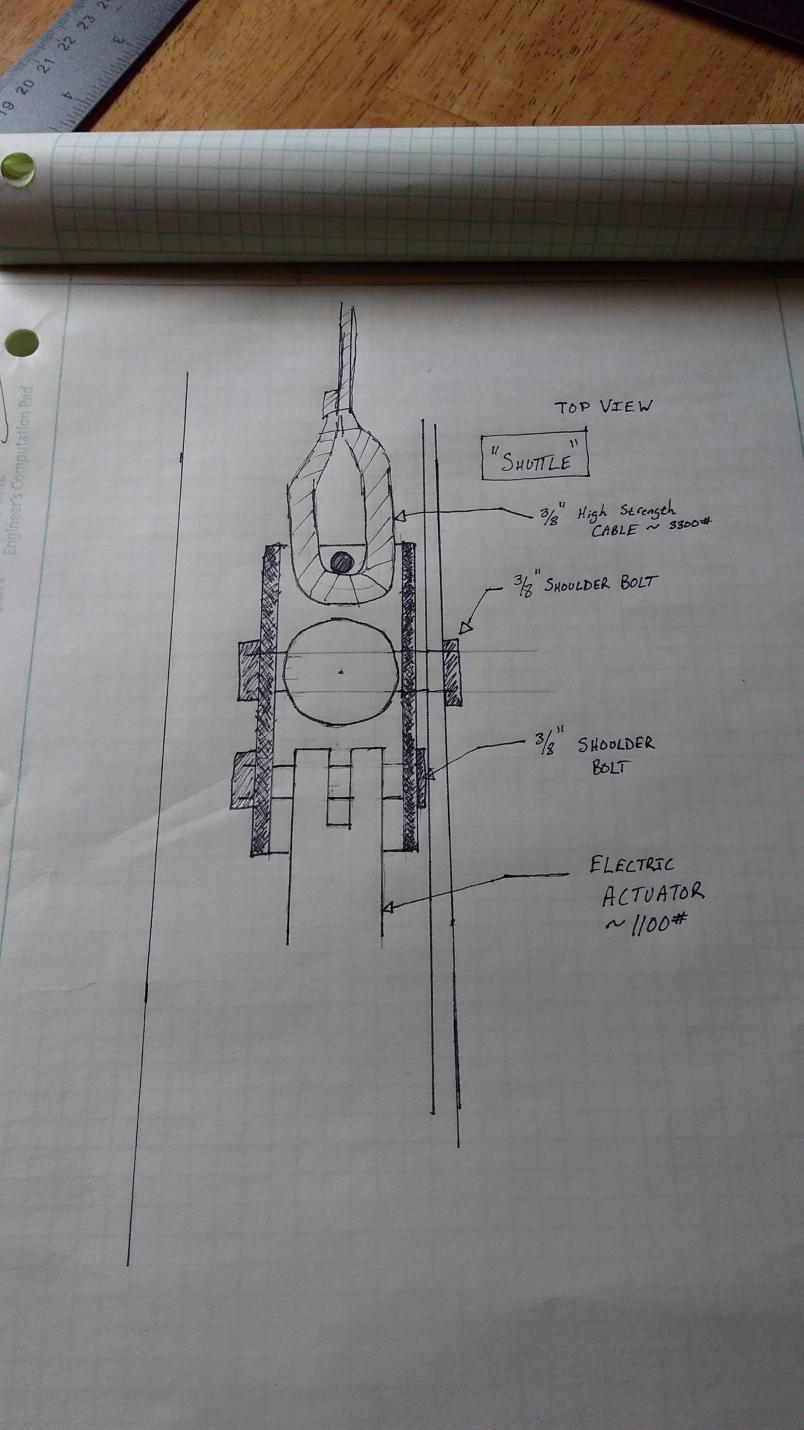

So I went went back to the drawing board and this is what I came up with.

Everyone be nice

Everyone be nice I havent drawn something so technical in a while. Its not exact but I hope you understand what Im going for here. I want to use an electric actuator and make a small "shuttle" that will carry the lifting arm forward. The chain will be replaced with a high strength steel cable that will be brought inline center and lay flat under neath the bar when closed. This is where it goes :

This is perhaps the most important and my least favorite thing about the penthouse design. With the chain on the outside of the bar it creates a lot of torsion and friction around the guided track its supposed to keep it in line. I believe friction is working strongly against me here. I wanted to redesign it before the install, but decided against it.

The "shuttle" will replace and center this design entirely and get rid of the small assist spring (the large spring remains). It will be made out of either high strength 1/4" thick 1-1/2" square tube by me, or sent out to be CNC milled. The biggest problem with this design, is moving the chain on center. When the top is lowered the bars lay down to 5 degrees and would contact the chain. This is why I want to use a steel cable that lays flat. I would likely have to make the shuttle longer and space the cable away from the bar. This would allow me enough room to bolt it in vertically.

This is the actuator that I have found that I think is best suitable for this application. I want to use the PA-11 D50 model in 24v with an 1100# thrust. It will go where the assist spring is currently. With a diameter of about 2" it will be a near perfect fit. A 12" model with collaspased length of ~25" will fit nearly perfect in the 28" I have available inside the track. I do not like the 12v model becasue of conflict with duty cycle and speed. At 0.05" per second under load it would take nearly 4 minutes to extend the 12" needed. With a duty cycle of 2 minutes I would have to wait 8 minutes once halfway up before continuing the lift. 12 minutes to lift the top is not happening.

I spoke with a product engineer and he assured me I could use a voltage step up 12v to 24v module if I met the app requirements. 5A per actuator. Amazon sells a 12v to 24v Step up with 20A rating. for under $50. With the 24v model I could lift the top in under 2 minutes with no pause for cool down.

The 1100# model sounds like extreme overkill for lifting the top, but Im actually concerned it wont be enough. The reason for this is when the top is down the bars are only 5 degrees above normal. This means that for every 100# of force along the normal line, only 8.7# will be translated into the upward direction. Which means the 1100# model give me a vertical force 95.9# per actuator or 191.7# for the pair. Once the top begin to move and the angle of the bars opens up, the 1100# will be much more than sufficient to get it all the way up and keep it up. Its the initial lift that has me hesitant, considering I plan on adding an additional 100# to the roof.

This has me thinking; if something like this would work, why isnt sportmobile doing it? Considering you wont meed to remove the top and material cost would be around $600.

I know there are a few engineers (Or guys that act like it) on this forum and some input would be appreciated. I know there are alot of your that would be more than happy for me to be the guinea pig on this one, but I want to think it through before dropping the cash and doing the work. I would really like to see this work, not just for my sake, but my girlfriend, and all the other guys I know are struggling getting it up and down (No pun intended

)

Product links:

https://www.actuatorzone.com/mini-tube-linear-actuator Open the PDF

https://www.amazon.com/uxcell-Conver...4v+step+up+20A

https://www.mcmaster.com/#standard-wire-rope/=169mk0o