|

|

02-06-2020, 11:49 AM

02-06-2020, 11:49 AM

|

#11

|

|

Senior Member

Join Date: Apr 2016

Posts: 185

|

This happend on my 2002 Quigley E350 Xlt

Call up Agile & ask for the 1” Dropdown sway-bar relocation kit.

It’s about $45 delivered.

There is no pic of it in the Installation Doc. I only found out of this because there it was on 1 of their Instagram pages.

Chasing this gremlin led to all new tie rod ends, sway bar & track bar bushings, multiple alignments, spin balances of the wheels.

At the time of the RIP installation I had Moog King Pins installed.

Check the Quigley part numbers for the Sway Bar - on mine they were same as a Ford PN. for a 2 wd E350.... 2 wd? hmmm

Interesting how it seems the Agile RIP Progressive springs must be longer if in there Instagram pic it shows this electroplated 1” piece of box steel lowering the position of the sway bar.

Yeah between the order of the front bumper, rear with swing out, LEDs from & rear (a lot of money) freight & instalation I was pretty dissspointed when I called Jesus and asked why this wasn’t in the installation instructions. I’d been chasing this gremlin for 11 months and change.

No there is no death wobble or anything up to 100 mph.

__________________

"A determined soul will do more with a rusty monkey wrench than a loafer will accomplish with all the tools in a machine shop."

White Buffalo - 2002 E350 4x Quigley 7.3 PSD... 52k mi

|

|

|

02-06-2020, 07:56 PM

02-06-2020, 07:56 PM

|

#12

|

|

Senior Member

Join Date: Dec 2018

Posts: 128

|

Quote:

Originally Posted by StraightOuttaBallard

This happend on my 2002 Quigley E350 Xlt

Call up Agile & ask for the 1” Dropdown sway-bar relocation kit.

It’s about $45 delivered.

...

Yeah between the order of the front bumper, rear with swing out, LEDs from & rear (a lot of money) freight & instalation I was pretty dissspointed when I called Jesus and asked why this wasn’t in the installation instructions. I’d been chasing this gremlin for 11 months and change.

No there is no death wobble or anything up to 100 mph.

|

Wait - so are you saying that everything - all handling, sway, and suspension wobble - was fixed by simply adding this 1" spacer bracket to the sway bar?

Is there anyway you could post a picture of what you're talking about? Either form Agile's page or your own rig? I'm afraid I'm a caveman who doesn't have an instagram or any other social media.

UPDATE - I think this is it, after digging around on Agile's website:

https://www.instagram.com/p/Bo2ekqenS1O/

this relocation thing looks like a piece of 1/4" (maybe 1/8") 1"x1" square stock that was just bolted in as a spacer for the sway bar ... hell I could make that for free at my work in like 20 minutes - yo StriaghtOuttaBallard - you mind posting up some dimensions on that piece?

Thanks!

__________________

'08 V10 6.8L Ford E350 Superduty extended

|

|

|

02-06-2020, 10:12 PM

02-06-2020, 10:12 PM

|

#13

|

|

Senior Member

Join Date: Nov 2012

Location: boise idaho

Posts: 2,625

|

Swaybar spacer heights can vary. I had to make mine 3” tall to have the swaybar properly positioned. But ya. Super easy to make yourself.

__________________

"understeer is when you hit the wall with the front of your car, oversteer is when you hit the wall with the rear of your car, horsepower is how hard your car hits the wall, and torque is how far your car moves the wall."

|

|

|

02-07-2020, 04:10 AM

02-07-2020, 04:10 AM

|

#14

|

|

Senior Member

Join Date: Apr 2016

Posts: 185

|

Over many miles a sway bar will put a torque into the system and slowly deteriorate the tie rod ends.

As this happens you get a vibration into the system - everything from tie rod ends, to the sway bar bushing, eventually the sway bar bracket (or was that on my Jeep XJ???), ovalizing of sway bar bushings. I had a Honda once that vibration in the front end even cupped the tires.

Part of what happened to me over the course of this gremlin chasing episode is that we even tried different amonunts of castor in the alignment as spec by Quigley...

I think if you get the kit [ to my knowledge the longer bolts are the difficult piece to get] that hopefully with another alignment and ball joints or king pins (don’t know which on your rig - just know the ‘02)

Hopefully you catch this early in the life cycle of the system and you can get to building your van out!

I’m out of the US atm - so Van isn’t with me.

I have a log of how the torqued sway bar because of no drop down spacer & all the parts that were thrown at it and alignment history proves over time that this happened to my rig. (I’m sure having info like this on the road - say 1300 mi away from home would be valuable)

One good thing that came of this saga is that I have all the diagrams and part numbers from Quigley, Moog, Agile in a notebook in my van. Hopefully I won’t need it! - it’s been about 4 or 5,000 miles since this last happend

|

|

|

02-07-2020, 11:35 AM

02-07-2020, 11:35 AM

|

#15

|

|

Senior Member

Join Date: Dec 2018

Posts: 128

|

Quote:

Originally Posted by shenrie

Swaybar spacer heights can vary. I had to make mine 3 tall to have the swaybar properly positioned. But ya. Super easy to make yourself.

|

OK - how do you know when the swaybar is properly positioned? Is there a certain distance from the frame it needs to be or should I be looking for the front portion of the swaybar to be perfectly parallel to the ground and axel?

I'll try to post up some pictures of my current sway bar setup when I get off work

__________________

'08 V10 6.8L Ford E350 Superduty extended

|

|

|

02-07-2020, 11:50 AM

02-07-2020, 11:50 AM

|

#16

|

|

Senior Member

Join Date: Jan 2009

Location: Corvallis, OR

Posts: 5,300

|

Quote:

Originally Posted by Mr.Anderson

OK - how do you know when the swaybar is properly positioned? Is there a certain distance from the frame it needs to be or should I be looking for the front portion of the swaybar to be perfectly parallel to the ground and axel?

|

You need to look at the end-links in relation to the sway bar where it points back towards the axle. End links should be 90 degress to the ends of the sway bar.

Whenever the van is lifted, and the sway bar is not dropped to accommodate (or longer end-links installed on '08+ front ends), then the sway bar's anti-roll stiffness changes. The steering on the vans without crossover steering, are affected by body-roll.

In addition to the front sway bar, a rear sway bar can help too on extended vans, especially when softer rear springs are installed.

__________________

2000 E450 dually V10 wagon

|

|

|

02-07-2020, 07:45 PM

02-07-2020, 07:45 PM

|

#17

|

|

Senior Member

Join Date: Apr 2016

Posts: 185

|

Quote:

Originally Posted by Mr.Anderson

OK - how do you know when the swaybar is properly positioned? Is there a certain distance from the frame it needs to be or should I be looking for the front portion of the swaybar to be perfectly parallel to the ground and axel?

I'll try to post up some pictures of my current sway bar setup when I get off work

|

I agree with what he said.

The Agile 1 box fits this, as do the longer bolts in the right length and thread pitch.

My guess is that the RIP Progressive Coils are either longer by an 1 or sit compressed longer than the Quigley Coils.

If you want to hear it I can post how I chased this gremlin in my front end for 11 months (ie what was changed when and what clues led me into this)

Ive seen people post about this problem before elsewhere on the internet and with so many pieces in this system it seems like either you get lucky and nip it in the bud early or you end up changing most of the parts in the overall system. And here all sorts of bandaid solutions like:

... run 2 steering dampers ... ... no run 2 in the same direction ... ... well I ran a Helewig Swaybar.... no you need an adjustable sway bar... ... no an adjustable track bar... ... but Moog everything.... ... no you need a Red Hat steering box ... ... you need moog bushings all around... ... Is your trackbar bracket cracked...

(btw I would look at the track bar bracket - because with oversized tires I hear these do crack)

Good thing about a solid axel is apparently an IFS I hear there can be 2 gremlins in each wheel ! At least it wasnt that way

|

|

|

02-18-2020, 05:29 PM

02-18-2020, 05:29 PM

|

#18

|

|

Senior Member

Join Date: Dec 2018

Posts: 128

|

Alright - back in town and back to chasing van gremlins:

Here are a couple pictures of the sway bar connection to the end link. From what carringb said it looks like the sway bar connects to the end link at a shallower angle closer to 45 degrees as opposed to 90. I can see how adding the spacer in on the sway bar bushing point would help correct that. I'll have to check the sway bar bushings as well, I'd imagine they haven't been replaced during the life of the vehicle and out in Arizona rubber doesn't do too well after 12 years.

Picture looking towards the passenger wheel from drivers side, I'm noticing the front of the sway bar is angled forward as opposed to down, is that normal or also from the need for a spacer?

Drivers side end link / sway bar

Same picture with lines for where it should go after a spacer install.

@straightouttabollard - can you elaborate on your 11 month gremlin chasing saga? This is good information to have posted for what people can be on the look for.

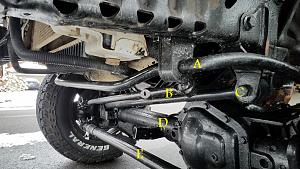

Also - stupid question since I'm still a n00b learning this front end - in the this picture of the front axel, do I have this correct:

sway bar (A)

Drag Link (B) ?

Track Bar (C) ?

Tie Rod (E) ?

So the track bar bracket that might be cracked is connected to the pitman arm and the wheel connection point?

Basing this off this other handy TJ diagram:

.jpg)

__________________

'08 V10 6.8L Ford E350 Superduty extended

|

|

|

02-19-2020, 06:11 PM

02-19-2020, 06:11 PM

|

#19

|

|

Senior Member

Join Date: Apr 2016

Posts: 185

|

Best place for diagrams w/labels (& part numbers) is to call Quigley & ask Sabrina to email you the build info.

My swaybar with the drop down kit, when parked on even surface & wheels pointed straight ahead sits 4 1/8” at centerline (Cl) below bottom of the Ibeam.

Unfortunately I don’t understand how to post pics on here. I looks like they need to be hosted somewhere and I don’t have an account for that.

To me it looks like you need the spacer.

I can’t tell from the pics on your vehicle if the adjustable sway bar ends are part of a 2008 Quigley front end?

My swaybar as per Quigley is the same as on a 2wd 2001 E350Superduty

4 Wheel Parts wanted to instal the adjustable swaybar ends at one point in time - generally they do good work - they also did an alignment and said they could only get it to align & “... it’s like your front end has a slight twist in it ...” I take that to mean they don’t work on many Quigley E series vans.

In my next post is a short history of how w/o the drop down kit & alignments the death wobble increased.

__________________

"A determined soul will do more with a rusty monkey wrench than a loafer will accomplish with all the tools in a machine shop."

White Buffalo - 2002 E350 4x Quigley 7.3 PSD... 52k mi

|

|

|

02-19-2020, 06:13 PM

02-19-2020, 06:13 PM

|

#20

|

|

Senior Member

Join Date: Apr 2016

Posts: 185

|

E350 Quigley Death Wobble

Here’s a list of everything I can think of that was redone on my 02 Quigley w/ Agile RIP:

7 Feb 2020

Moog kin pins when RIP installed.

Extra load specific RIP rear leaves & new u bolts

check front wheel bearings & repack w/ grease

1st Alignment post RIP install

After about 2200 miles:

1st go round at solving this mystery

Spin balance front wheels

Order new front discs from Quigley - they were cupped - couldn’t resurface them -

Re- Alignment

Retorque rear spring pack u-bolts

After about 2500 miles:

Spin balance again

Sent Fox steering Stabilizer to Agile for rebuild

Re alignment to Quigley Castor

Track down all part numbers & order what’s installed next go round

After about 2900 miles:

Order/ install Mood Sway bar bushings & track bar drop bushings

Order & install new sway bar - hmm Ford/ Quigley part number the same as 2wd E350 - how can this be?

Shop finds one of the sway bar bushings band bolts stripped - have to tap & use 11 or 12 mm Bolt - got it installed but shop says “ that can’t be the right sway bar “

Call Quigley they confirm part number

Didn’t install sway bushings that go into solid axel - I haven’t had time to fab a tool to press them in - the original ones are ok

Order all tie rod ends by Moog

Special Quigley tie rod w/ tie rod end

2950 miles:

Install:

All new Moog Tie rod ends

Special Quigly

Tierod w/ tie rod end

Track bar bushings

at 4 Wheel Parts

They say it took multiple alignments and test drives to get right “... it’s like the whole system had to be aligned with a torque to the axel to function right...”

Then in less than 100 mi the death wobble starts again but at a different speed & not as extreme. Then the city driving speed wobble won’t end unless you pull over. Now I’m thinking wtf? Before it was at hiway speeds - at least I could drive it in the city.

A month goes by and I see that Instagram pic.

Order & install and it aligns perfectly.

So hopefully if this is corrected before parts start deteriorating you will be spared from this saga.

I wrote this last week while not actually not in the US where the van is - this whole saga was such a mystery that it sticks in my mind.

I made a notebook with all the diagrams, part numbers, history, receipts, all the alignment print outs and it’s in my van - hopefully I will never need it again! I have it under the seat Incase if I need it while on the road.

I think it’s been about 4 or 5,000 miles w/o incident.

I know from other vehicles, work, what I learned in Engineering School, and life experience that any system with rotating mass, vibrations, oscillations, 3 dimensional forces, wearing parts, the parts sourced from a parts supply chain - can turn into detective work - even drawing diagrams of how it should function

__________________

"A determined soul will do more with a rusty monkey wrench than a loafer will accomplish with all the tools in a machine shop."

White Buffalo - 2002 E350 4x Quigley 7.3 PSD... 52k mi

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|