......140 lbs of brake rotors.....

So, I've decided to upgrade my brakes.

My van is a 2008 E350 with a kingpin Dana 60 front axle, converted at Advanced 4X4. Apparently, Advanced uses Chevy outer knuckles and mid 2000+ Chevy truck/Suburban rotors and calipers, at least on my van anyway.

So, after some research and some guidance from BajaSportsmobile, I picked up a few rotors..

Right to left are: my existing Chevy rotors (12.8" diameter x 1.5" thick, 8 x 6.5 lug), Ford F250 Superduty rotors (13.66" dia x 1.5" thick 8 x 170mm lug), mid 2000's Dodge 2500/3500 truck rotors (13.9" diameter x 1.4" thick 8 x 6.5" lug) and F450 rotors (14.5" diameter x 1.5" thick 8 x 170mm lug)

...the keen observer will note that the Dodge and the F250 rotors have 16 holes in them; I added another set of 8 x 6.5 holes with my rotary table and mill. The Dodge stock lug pattern is 8 x 6.5 but the holes are much larger than my studs, so they got modified.

I've been at this project for awhile, and have gone around with a number of rotors over the past few weeks. My initial setup idea was to use the Dodge rotors as they were the correct lug pattern and slightly larger than the F250 rotors although, as mentioned I ended up drilling a new set of holes anyway and the rotors are a bit thinner than the Fords.

For reference, the stock 2008+ E350 rotors are thicker than any of these rotors by a couple of mm.....

I also picked up some 2008+ E350 calipers......the same ones that would have come on my van from the factory.

The kingpin Dana 60 uses removable caliper brackets that also hold the spindles to the knuckles; later ball joint type axles have the caliper mounting bosses cast into the knuckles. The brackets on my van are fabricated weldments from Advanced to hold the Chevy components, and the 6 hole pattern in the brackets means Chevy knuckles. I'll take a picture of these and post if I can remember.....

So, next up was to fabricate/design some wood patterns/mock-up caliper brackets.....from left to right three attempts from primitive to so-so....

Note that the last iteration has two sets of holes; this was to rotate the bracket slightly so that the upper caliper mounting bolt will clear the steering stuff on the top of the passenger side knuckle.

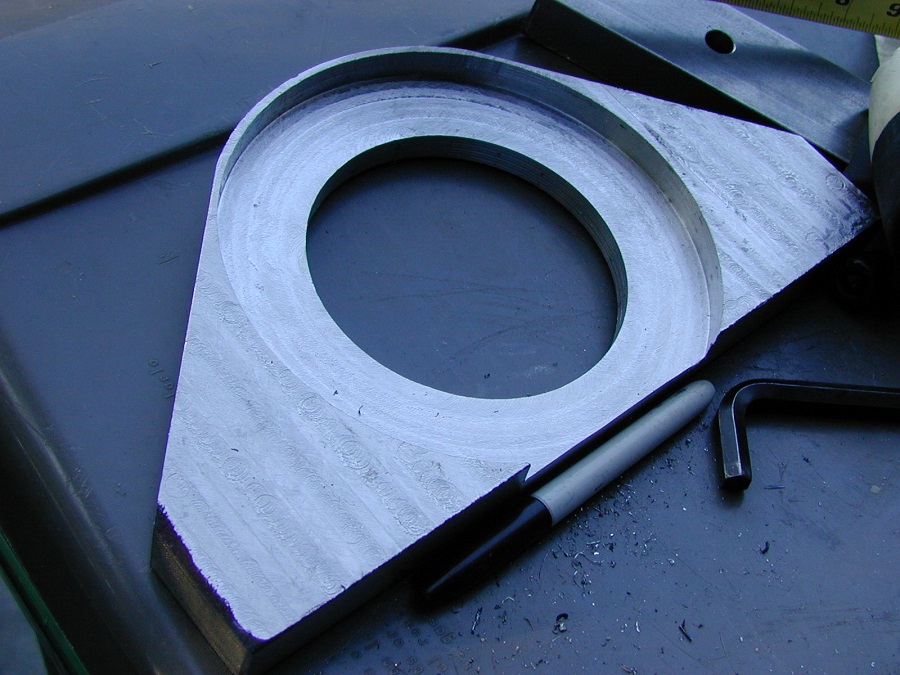

Here is a picture of the Dodge rotor, new calipers and the last wooden pattern/mock-up

Once the pattern looked good, I bought some 1" thick mild steel plate and had a fabricater torch it to rough dimensions......plate steel is rediculously expensive retail! $75 for the plate and $75 to torch......and another $25 to weld...yet to come.

here are the rough cut plates

.....and here they are after about a zillion hours of milling.....did I mention that steel is harder than woodpecker lips to machine? ...and the chips come off the piece scorching hot...pro tip....milling steel goes way faster when using a roughing end mill...like 10X faster.

more machining and bolted on ears (ears will be welded shortly)

The crude notch in the bracket is for the ABS sensor; I just duplicated what Advanced machined into the brackets that are on the van.

.....more to come.......