I'm posting this for posterity (and my own future reference) or anybody else that might run across the same issues.

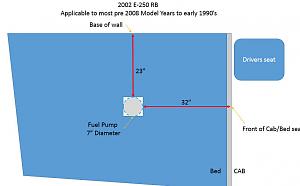

The pictures of a 2002 E-250 RB, but the dimensions between the cab and the fuel pump assy location are the same on the EB.

Applicable to most pre-2008 Model Years to the early 1990’s

I bought this 2002 E-250 work van for a song because it has a bad fuel pump. The van had 225K miles and had been used as a work truck by an older gentleman who had now passed.

The floor was beat up so I decided to cut a hole in the floor to access the fuel pump. As you will see I cut out 3 sides and peeled back the rest like a sardine can. I put a length of flat bar stock under the floor so I could bend the flap back into its original position to screw it down onto the flat stock. I did some welding to close it up but eventually realized that was a waste of time and the flap would be better if I ever needed to get in again. (which I did have to, which I will describe later on).

Closed Access. I was not exactly sure where to cut, so this post is to more precisely locate the hole if starting a new one.

Open Access

Measurements from the driver's side base of the wall.

The measurement from the front of Cab/Bed seam (so you can catch a tape measure on it)

Schematic view of pump assembly location and minimum access hole size. There is some wiggle room here by turning the pump assy so adjust as per your preference